Sewage Treatment Plant

Over the last 25 – 30 years the introduction of the Package Sewage Treatment Plant has

revolutionized the way that we handle and think about private foul drainage.

The septic tank was, until recently, the most common method of dealing with domestic foul waste.

However, increased understanding and concern about pollutants has driven the need for more

effective and safe treatment of waste. Package sewage treatment plants meet these requirements

most effectively, and in the majority of cases, is the preferred choice.

The main benefits of package sewage treatment plants are that: discharges are cleaner; in some

cases discharges can be sent directly to a water course (subject to Environment Agency consent);

they do not generally smell; and soakaways can be up to 20% shorter than that for a septic tank

and have a far longer life span.

Package Sewage Treatment Plants come in many guises, but all aim to treat human effluent to a

standard acceptable to the Environment Agency. The industry accepted standard is expressed

as:

- 20 milligrams per litre BOD (Bio-Chemical Oxygen Demand)

- 30 milligrams per litre of suspended solids

- 20 milligrams per litre of Ammonia

Most systems are designed to achieve these standards. Compare this with the discharge from a

typical septic tank which can often be higher than 150 milligrams per litre BOD and suspended

solids, with Ammonia figures being dependant on the type of usage (very high from premises etc).

More stringent discharge standards are often demanded to take account of dilution values of a

water course or where fish spawning needs to be protected. The discharge to a pond or small lake

should be avoided due to the remote possibility of bacterial carry-over. Bacteria can multiply

in the friendly environment of static or nearly static waters.

For all discharges to a watercourse, and for all discharges in excess of 2 cubic metres per day

from 1 house, a ‘Consent to Discharge’ must be applied for from the Environment Agency.

Where discharges are less than 2 cubic metres per day to a soakaway a ’Building Control Notice’

from the local council is sufficient. In either case, any soakaway has to be justified by a

percolation test, which determines the suitability of the ground and the length of the soakaway

required. For discharges in excess of 2 cubic metres per day a soil profile must also be

submitted, to determine the composite of the soil and the depth of each layer.

(See Soakaways)

Package Sewage Treatment Plants essentially encourage naturally occurring bacteria within sewage

to form a substance know as bio-mass, which breaks down the material and thereby ‘cleans’ the

fluid. This process is carried out by introducing air and recycling the effluent. In all, but

the more expensive systems, the plants only treat fluids, and non-soluble matters are screened

out in the inlet chamber. There are basically four different ways of introducing air and the

growth of bio-mass.

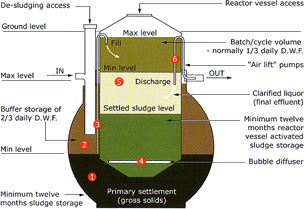

1. By forcing air into the fluid to ‘bubble’ it – agitated sludge method. The bacterium is

grown in the fluid to good effect and is used in large municipal installations and small plants

alike – the fluid is then drawn off and after settlement, the clear liquid discharged.

A Sequential Batch Reactor (SBR) uses this method, but with the added benefit of controlling

the volume of each treated batch, allowing for settlement and de-nitrification, to produce an

extra clean discharge. The more refined versions of the SBR system also treat the solids so

reducing the sludge content.

2. By introducing air into the base of the fluid and passing it through a submerged media to

encourage bio-mass growth on the surface of the media. Used in small plants with good effect,

and in larger plants as part of a modular treatment.

3. By the use of the pressure of introduced air, to lift the fluid and distribute it over a bale

above the fluid level. Has the same effect as the above system, but in times of electric failure

the bio-mass stays healthy for a longer period.

4. By rotating a drum/wheel the fluid is mixed with air and replenished with bacteria allowing

the bio-mass to grow on the vanes. Has mechanical functions but very effective in treating

effluent.

4. By rotating a drum/wheel the fluid is mixed with air and replenished with bacteria allowing

the bio-mass to grow on the vanes. Has mechanical functions but very effective in treating

effluent.

There are variations to the above but screening, introduction of air, and settlement are inherent

features of all plants.

S&B Services is able to supply and install any of the above plants, and to advise

customers of the choices available, and to independently recommend the most suitable model for

each location.

See ‘Site Assessment and Products’.

All descriptions are, by necessity, brief, more detailed information can be supplied on

request.

Treatment Plants are available for single houses and small to medium sized housing estates.

Some plants are even able to process animal waste, including blood, brewery waste and milk.

Most domestic plants should be gravity fed, and if the outfall needs to be at a higher level,

pump-sets can be used to lift the treated effluent. Some treatment plants have an integral pump

thus eliminating the need for a separate installation. If it is impossible to gravity feed a

treatment plant, then the addition of a primary settlement tank is recommended before the plant,

to receive the pumped waste, and the untreated effluent is fed by gravity to the plant. In small

installations an inspection chamber can be used to slow the discharges in order to reduce the

turbulence that a pumped ingress can create. The use of a Vortex pump will reduce the breaking

down of the solid matter and reduce the suspended solids level, allowing the plant to screen out

the non-soluble material.

Treatment Plants can also be used to ‘final wash’ the outflow from septic tanks, as can reed

beds and sand filters. Further details on these can be provided on request.

Treatment Plants come in various sizes and all, but a few, have a standard invert level of 1

metre, with shallower and deeper ones on request.

Optional extras such as power failure alarms and high level alarms are available for all plants

and can be ordered via S&B Services.